OBJECTIVES

After completing this unit, the student should be

able to:

• Identify the classes (lớp) of jigs and fixtures (fixtures).

• Identify the types (loại) of jigs and fixtures (fixtures).

• Choose a class and type of jig and fixture for

selected operations on sample parts.

JIGS AND FIXTURES(fixtures)

Jigs and fixtures (fixtures) are production-workholding devices

used to manufacture duplicate parts accurately. The

correct relationship and alignment between the cutter,

or other tool, and the workpiece must be maintained.

To do this, a jig or fixture is designed and built to hold,

support, and locate every part to ensure that each is

drilled or machined within the specified limits.

Jigs and fixtures (fixtures) are so closely related that the

terms are sometimes confused or used interchangeably.

The difference is in the way the tool is guided to the

workpiece.

A jig is a special device that holds, supports, or is

placed on a part to be machined. It is a production

tool made so that it not only locates and holds the

workpiece but also guides the cutting tool as the operation

is performed. Jigs are usually fitted with hardened

steel bushings for guiding drills or other cutting

tools (Figure 2–1A).

As a rule, small jigs are not fastened to the drill

press table. If, however, holes above .25 inch in diameter

are to be drilled, it is usually necessary to fasten

the jig to the table securely.

A fixture is a production tool that locates, holds,

and supports the work securely so the required

machining operations can be performed. Set blocks

and feeler or thickness gauges are used with fixtures (fixtures)

to reference the cutter to the workpiece (Figure 2–1B).

A fixture should be securely fastened to the table of

the machine upon which the work is done. Though

largely used on milling machines, fixtures (fixtures) are also

designed to hold work for various operations on most

of the standard machine tools.

Fixtures (fixtures) vary in design from relatively simple

tools to expensive, complicated devices. Fixtures (fixtures) also

help to simplify metalworking operations performed

on special equipment.

CLASSES OF JIGS

Jigs may be divided into two general classes: boring

jigs and drill jigs. Boring jigs are used to bore holes

that either are too large to drill or must be made an

odd size (Figure 2–2). Drill jigs are used to drill,ream, tap, chamfer, counterbore, countersink, reverse

spotface, or reverse countersink (Figure 2–3). The

basic jig is almost the same for either machining operation.

The only difference is in the size of the bushings

used.

TYPES OF JIGS

Drill jigs may be divided into two general types, open

and closed. Open jigs are for simple operations where

work is done on only one side of the part. Closed, or

box, jigs are used for parts that must be machined on

more than one side. The names used to identify these

jigs refer to how the tool is built.

Template jigs are normally used for accuracy rather

than speed. This type of jig fits over, on, or into the work

and is not usually clamped (Figure 2–4). Templates are

the least expensive and simplest type of jig to use. They

may or may not have bushings. When bushings are not

used, the whole jig plate is normally hardened.

Plate jigs are similar to templates (Figure 2–5).

The only difference is that plate jigs have built-in

clamps to hold the work. These jigs can also be made

with or without bushings, depending on the number

of parts to be made. Plate jigs are sometimes made

with legs to raise the jig off the table for large work.

This style is called a table jig (Figure 2–6).

Sandwich jigs are a form of plate jig with a back

plate (Figure 2–7). This type of jig is ideal for thin or

soft parts that could bend or warp in another style of

jig. Here again, the use of bushings is determined by

the number of parts to be made.

Angle-plate jigs are used to hold parts that are

machined at right angles to their mounting locators

(Figure 2–8). Pulleys, collars, and gears are some of

the parts that use this type of jig. A variation is the

modified angle-plate jig, which is used for machining

angles other than 90 degrees (Figure 2–9). Both of

these examples have clearance problems with the cutting

tool. As the drill exits the product being drilled,

it has little or no room for the drill point to clear the

product completely, produce a round hole all the way

through the part wall, and avoid drilling the part locator.

This is most noticeable in Figure 2–9, where an

angled hole requires additional clearance to the

relieved portion of the part locator. Additional clearance

here would allow the drill to complete the hole

and avoid drilling the relieved portion of the locator.

The part locator will most likely be hardened and the drill will be lost as a result of any attempted drilling.

Additional clearance on the relieved diameter of the

part locator may be possible. A larger clearance hole

in the locator could also be added if the relieved

diameter cannot be reduced. The additional design

consideration added to the locator would include the

feature to provide the correct orientation of this clearance

hole or machined relief to line up with the bushing

location.

Box jigs, or tumble jigs, usually totally surround

the part (Figure 2–10). This style of jig allows the

part to be completely machined on every surface

without the need to reposition the work in the jig.

Channel jigs are the simplest form of box jig (Figure

2–11). The work is held between two sides and

machined from the third side. In some cases, where jig

feet are used, the work can be machined on three sides.

Leaf jigs are small box jigs with a hinged leaf to

allow for easier loading and unloading (Figure 2–12).

The main differences between leaf jigs and box jigs

are size and part location. Leaf jigs are normally

smaller than box jigs and are sometimes made so that

they do not completely surround the part. They are

usually equipped with a handle for easier movement.

Indexing jigs are used to accurately space holes

or other machined areas around a part. To do this, the jig uses either the part itself or a reference plate and a

plunger (Figure 2–13). Larger indexing jigs are called

rotary jigs.

Trunnion jigs are a form of rotary jig for very

large or odd-shaped parts (Figure 2–14). The part is

first put into a box-type carrier and then loaded on the

trunnion. This jig is well suited for large, heavy parts

that must be machined with several separate platetype

jigs.

Pump jigs are commercially made jigs that must be

adapted by the user (Figure 2–15). The lever-activated

plate makes this tool very fast to load and unload. Since

the tool is already made and only needs to be modified,

a great deal of time is saved by using this jig.

Multistation jigs are made in any of the forms

already discussed (Figure 2–16). The main feature of

this jig is how it locates the work. While one part is

drilled, another can be reamed and a third counterbored.

The final station is used for unloading the finished

parts and loading fresh parts. This jig is

commonly used on multiple-spindle machines. It

could also work on single-spindle models.

There are several other jigs that are combinations

of the types described. These complex jigs are often so

specialized that they cannot be classified. Regardless of

the jig selected, it must suit the part, perform the operation

accurately, and be simple and safe to operate.

TYPES OF FIXTURES

The names used to describe the various types of fixtures (fixtures)

are determined mainly by how the tool is built.

Jigs and fixtures (fixtures) are made basically the same way as

far as locators and positioners are concerned. The

main construction difference is mass. Because of the

increased tool forces, fixtures (fixtures) are built stronger and

heavier than a jig would be for the same part.

Plate fixtures (fixtures) are the simplest form of fixture

(Figure 2–17). The basic fixture is made from a flat

plate that has a variety of clamps and locators to hold

and locate the part. The simplicity of this fixture

makes it useful for most machining operations. Its

adaptability makes it popular.

The angle-plate fixture is a variation of the plate

fixture (Figure 2–18). With this tool, the part is normally

machined at a right angle to its locator. While most angle-plate fixtures are made at 90 degrees,

there are times when other angles are needed. In

these cases, a modified angle-plate fixture can be

used (Figure 2–19).

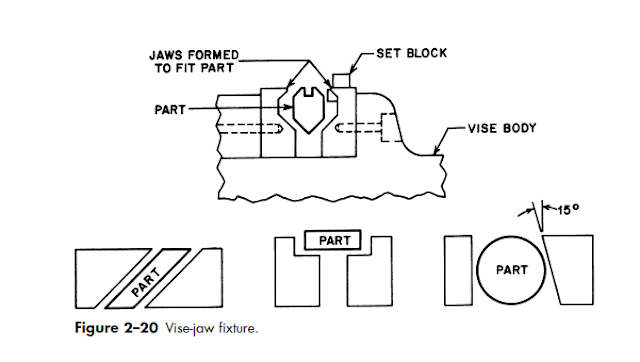

Vise-jaw fixtures (fixtures) are used for machining small

parts (Figure 2–20). With this type of tool, the standard

vise jaws are replaced with jaws that are formed

to fit the part. Vise-jaw fixtures (fixtures) are the least expen- sive type of fixture to make. Their use is limited only

by the sizes of the vises available.

Indexing fixtures (fixtures) are very similar to indexing jigs

(Figure 2–21). These fixtures (fixtures) are used for machining

parts that must have machined details evenly spaced.

The parts shown in Figure 2–22 are examples of the

uses of an indexing fixture.

Multistation fixtures (fixtures) are used primarily for highspeed,

high-volume production runs, where the

machining cycle must be continuous. Duplex fixtures (fixtures)

are the simplest form of multistation fixture, using

only two stations (Figure 2–23). This form allows the

loading and unloading operations to be performed

while the machining operation is in progress. For

example, once the machining operation is complete at

station 1, the tool is revolved and the cycle is repeated

at station 2. At the same time, the part is unloaded at

station 1 and a fresh part is loaded.

Profiling fixtures (fixtures) are used to guide tools for

machining contours that the machine cannot normally

follow. These contours can be either internal or external.

Since the fixture continuously contacts the tool,

an incorrectly cut shape is almost impossible. The

operation in Figure 2–24 shows how the cam is accurately

cut by maintaining contact between the fixture

and the bearing on the milling cutter. This bearing is

an important part of the tool and must always be

used.

CLASSIFICATION OF FIXTURES

Fixtures (fixtures) are normally classified by the type of

machine on which they are used. Fixtures (fixtures) can also be

identified by a subclassification. For example, if a

fixture is designed to be used on a milling machine, it

is called a milling fixture. If the task it is intended to

perform is straddle milling, it is called a straddlemilling

fixture. The same principle applies to a lathe

fixture that is designed to machine radii. It is called a

lathe-radius fixture.

The following is a partial list of production operations

that use fixtures (fixtures):

Assembling Lapping

Boring Milling

Broaching Planing

Drilling Sawing

Forming Shaping

Gauging Stamping

Grinding Tapping

Heat treating Testing

Honing Turning

Inspecting Welding

SUMMARY

The following important concepts were presented in

this unit:

• Jigs and fixtures (fixtures) are production workholding

devices designed to hold, support, and locate a

workpiece.

– A jig guides the cutting tool with a drill bushing.

– A fixture references the cutting tool with a set

block and feeler, or thickness gauges.

• Jigs are divided into two general classes: drill jigs

and boring jigs. • The type of jig is determined by how it is built.

The two types of jigs are open and closed.

– Template, plate, table, sandwich, and angleplate

jigs are all open jigs.

– Box, channel, and leaf jigs are all closed jigs.

• Other variations, such as indexing, rotary, trunnion,

pump, and multistation jigs, are made as

either open or closed jigs.

• Fixture types are determined by the way they are

built. The most common types are plate, angleplate,

vise-jaw, indexing, and multistation fixtures (fixtures).

• Fixture classes are determined by the machine

tools on which they are used and sometimes by the

operations performed. A fixture used for a straddlemilling

operation is classed as a mill fixture, but it

may also be classed as a straddle-milling fixture.

REVIEW

1. What is the difference between a jig and a fixture?

2. How are jigs and fixtures (fixtures) normally identified?

3. What are set blocks used for?

4. What class of jig would normally be used to tap

holes?

5. A gang-milling fixture is actually what class of tool?

6. Analyze the following part drawings and operations

to be performed and select the best jig or

fixture for each.

A. Figure 2–25. Operation: Mill a slot .250 inch

by .250 inch.

1. Box fixture

2. Duplex fixture

3. Vise-jaw fixture

B. Figure 2–26. Operation: Drill four .500-inchdiameter

holes.

1. Plate jig

2. Angle-plate jig

3. Channel jig

C. Figure 2–27. Operation: Drill four holes (two

.62-inch and two .25-inch).

1. Channel jig

2. Plate jig

3. Box jig

D. Figure 2–28. Operation: Drill four holes, .50

inch in diameter.

1. Box jig

2. Angle-plate jig

3. Template jig

E. Figure 2–29. Operation: Mill a shoulder .75

inch by .75 inch by .38 inch.

1. Plate fixture

2. Angle-plate fixture

3. Indexing fixture

do you have answer for this review question?

ReplyDeleteJig manufacturing companies specialize in creating precise tools that guide the manufacturing process, ensuring accuracy and consistency. They play a key role in industries like aerospace, automotive, and electronics, providing customized solutions to improve production efficiency and reduce costs. jig manufacturing companies

ReplyDelete